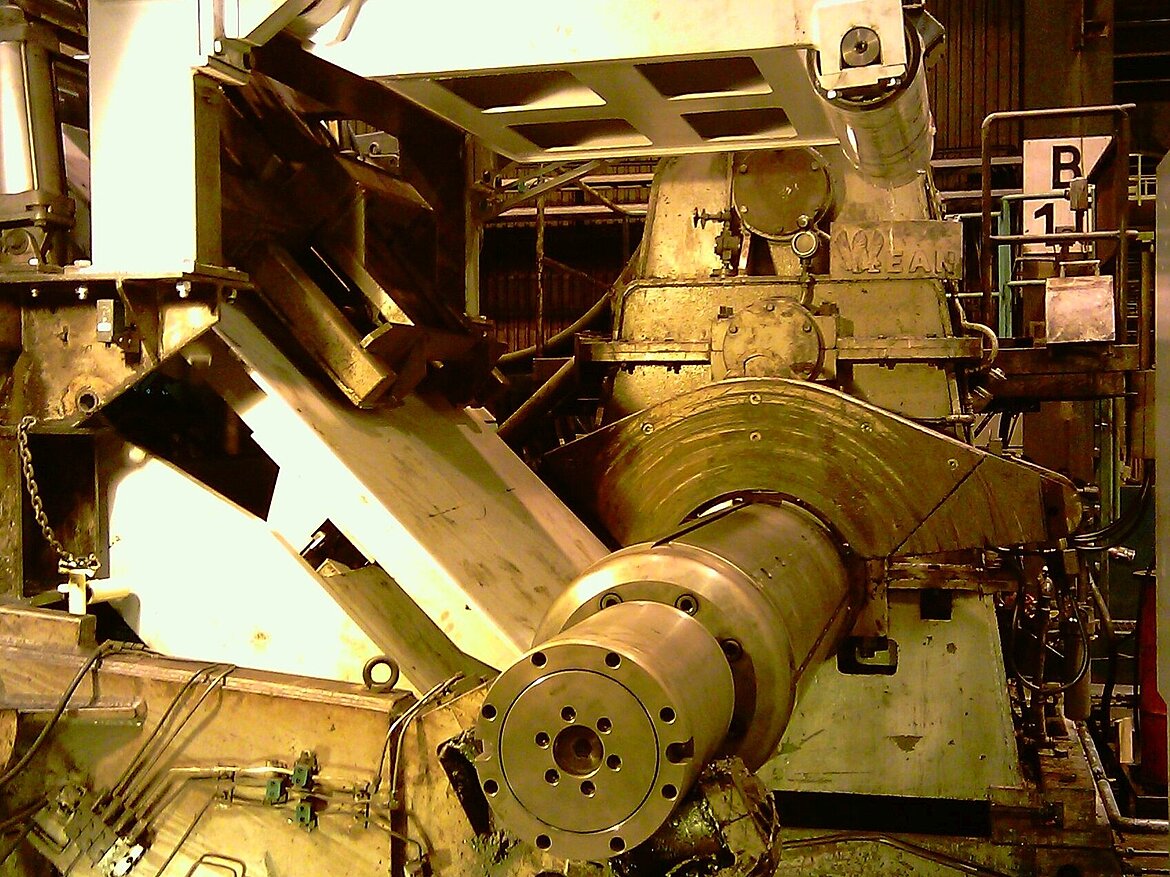

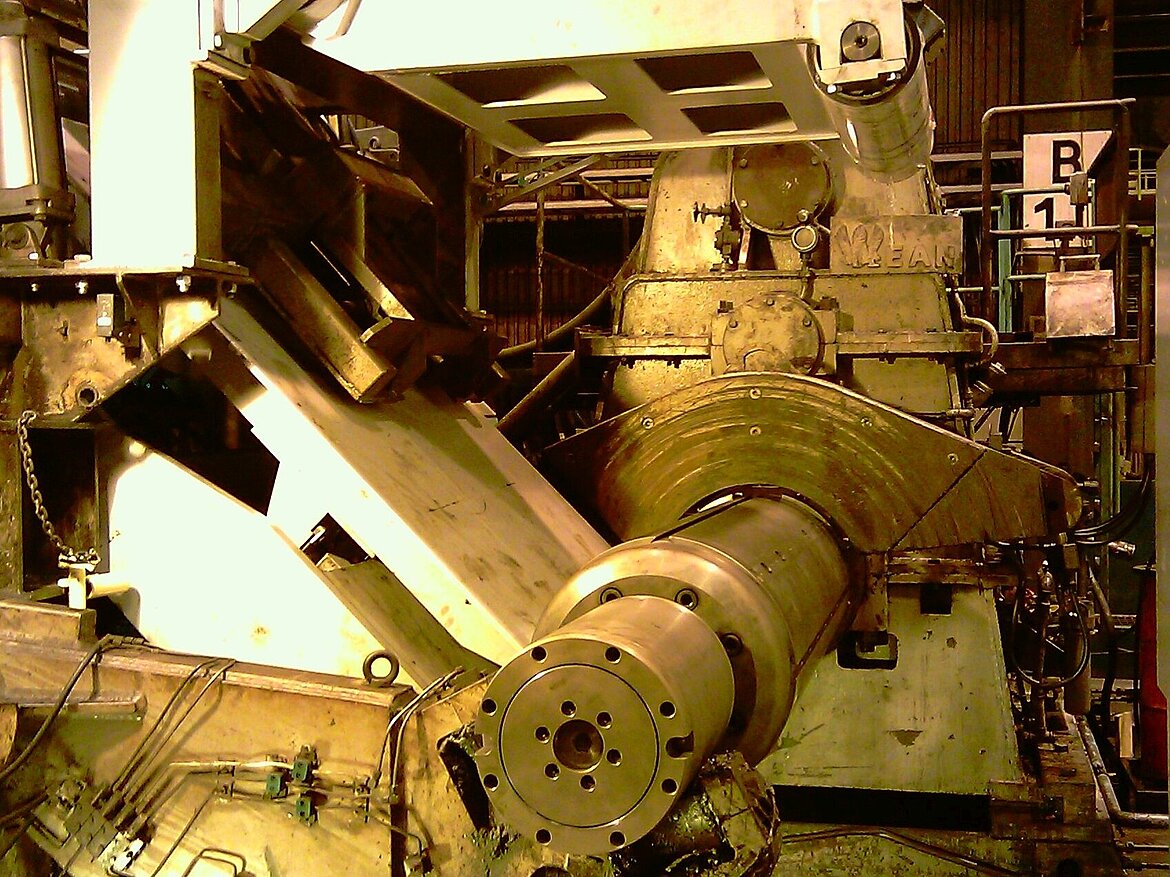

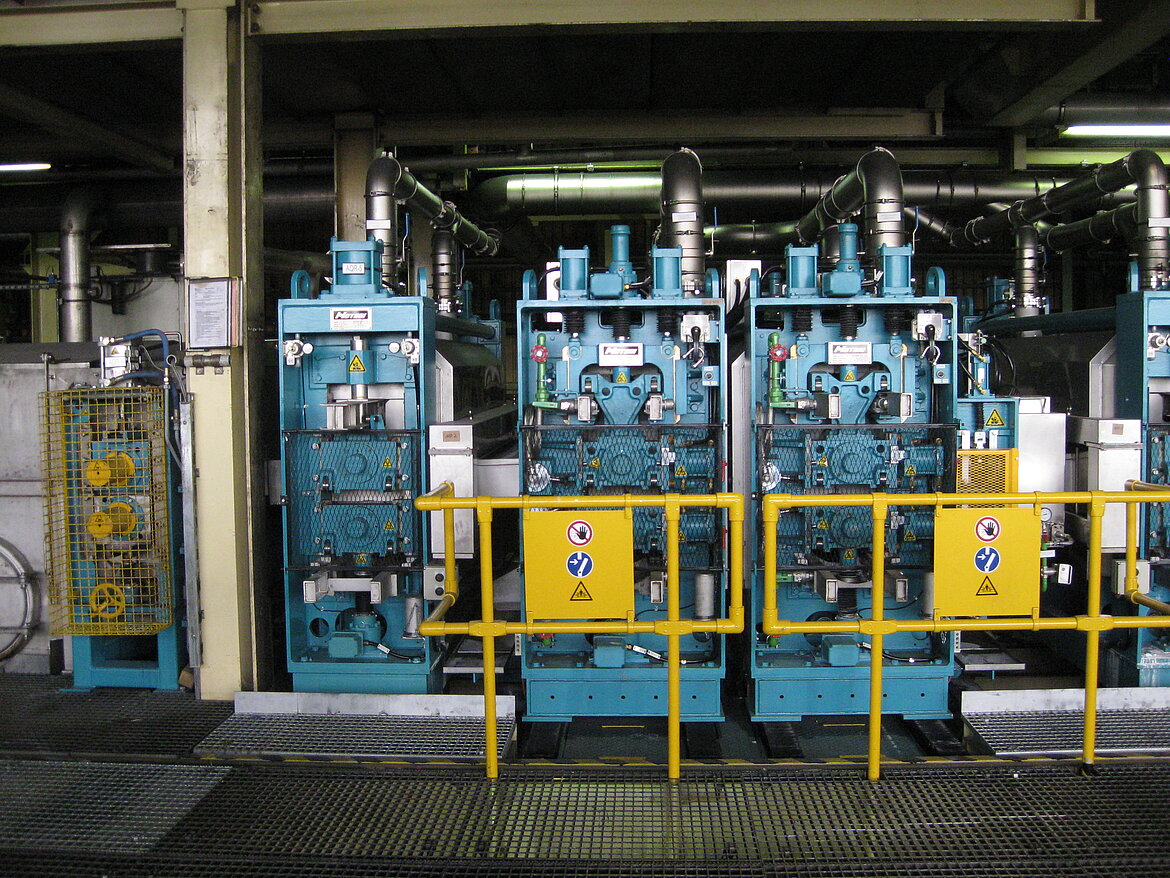

DUMA-BANDZINK offers a large variety of solutions for the individual requirements of their customers – everything from one source. Due to the long-lasting experiences in engineering equipment for strip processing lines DUMA-BANDZINK GmbH offers an extensive know-how for modernizations and modifications in the steel and aluminium industry. There are several reasons for a modernization such as integrating additional functions into existing lines e.g. a side trimmer, performance optimization or exchange of aging machines.