Innovative Lösungen

Arbeit mit Leidenschaft

Veredlung von Oberflächen

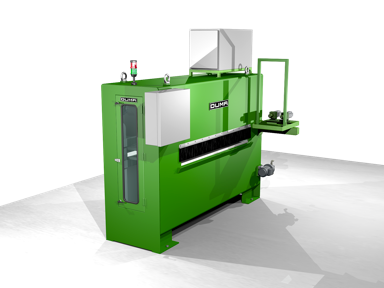

Die DUMA-BANDZINK GmbH ist ein international tätiges Unternehmen des Anlagen- und Maschinenbaus mit Hauptsitz in Mönchengladbach, Deutschland. Geschäftsfelder des Unternehmens sind die Entwicklung, Konstruktion, Fertigung, Montage und Reparatur von Maschinen und Anlagen im Bereich von Bandveredelungsanlagen und Kaltwalzwerken der Stahlindustrie sowie der technische Service und das Ersatzteilgeschäft für vorgenannte Anlagen.

News & Press

Mönchengladbach, 30. April 2024

Mönchengladbach, 30. April 2024

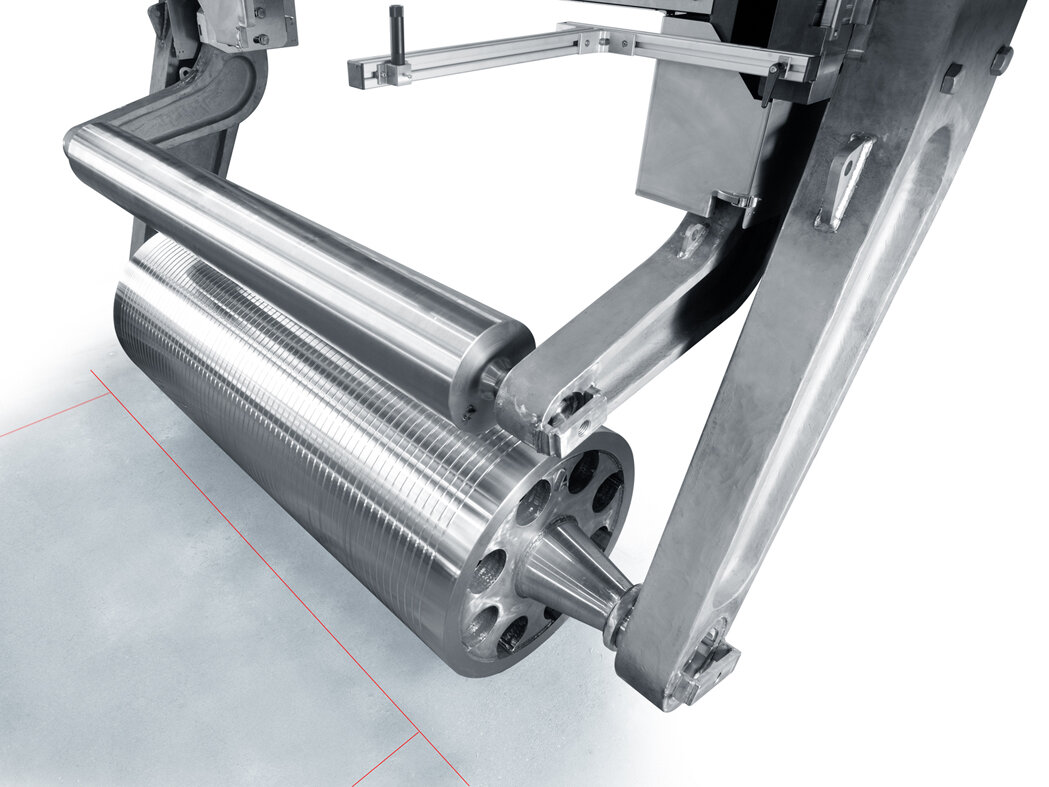

Angang Guangzhou Automotive Steel bestellt zweite Feuerverzinkungslinie bei SMS group mit dem Abstreifdüsensystem von…

Mönchengladbach, 25. Januar 2024

Mönchengladbach, 25. Januar 2024

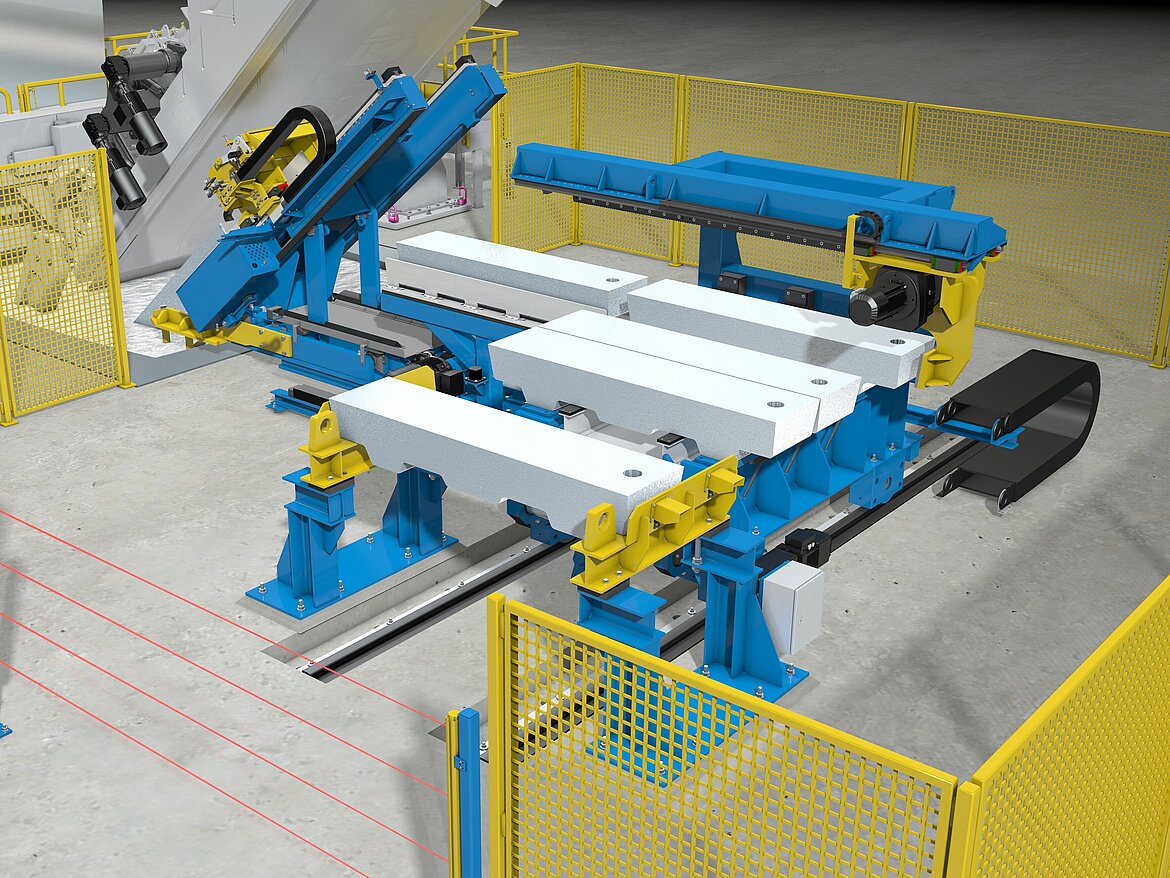

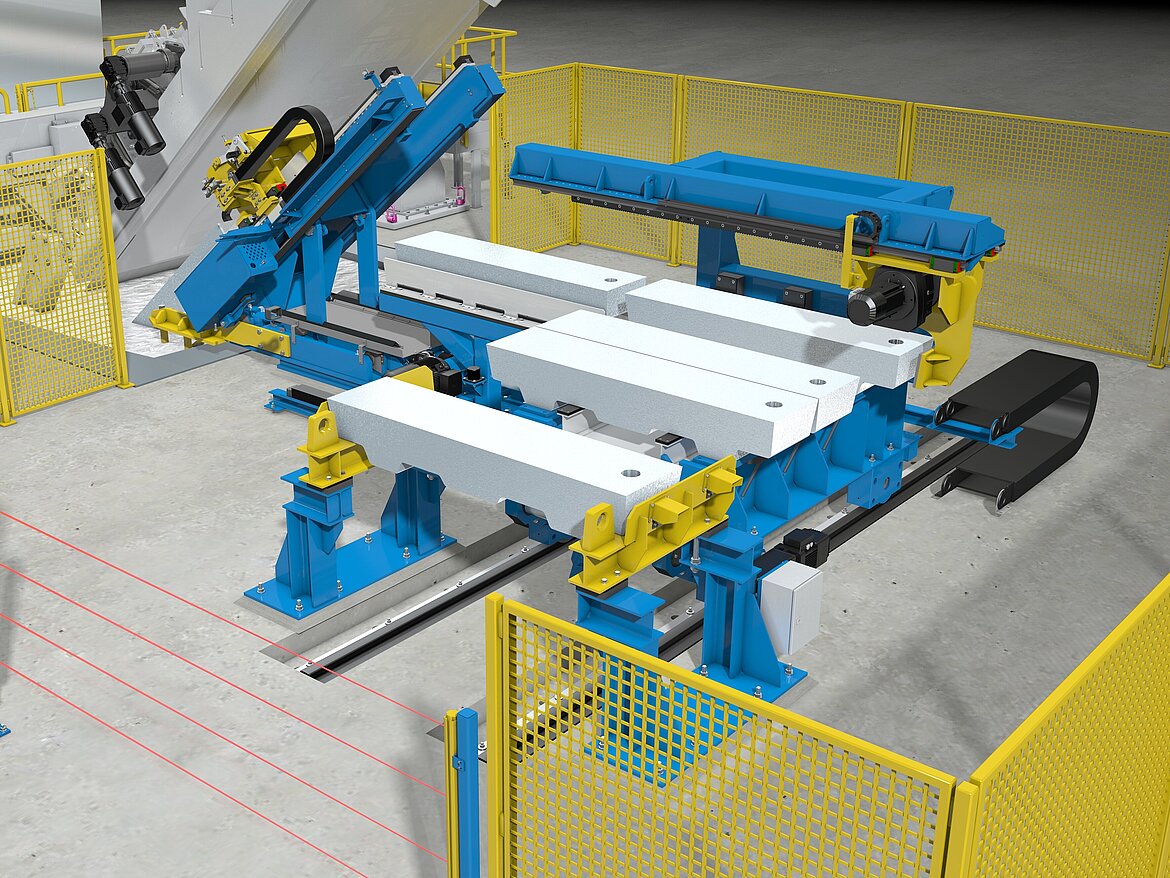

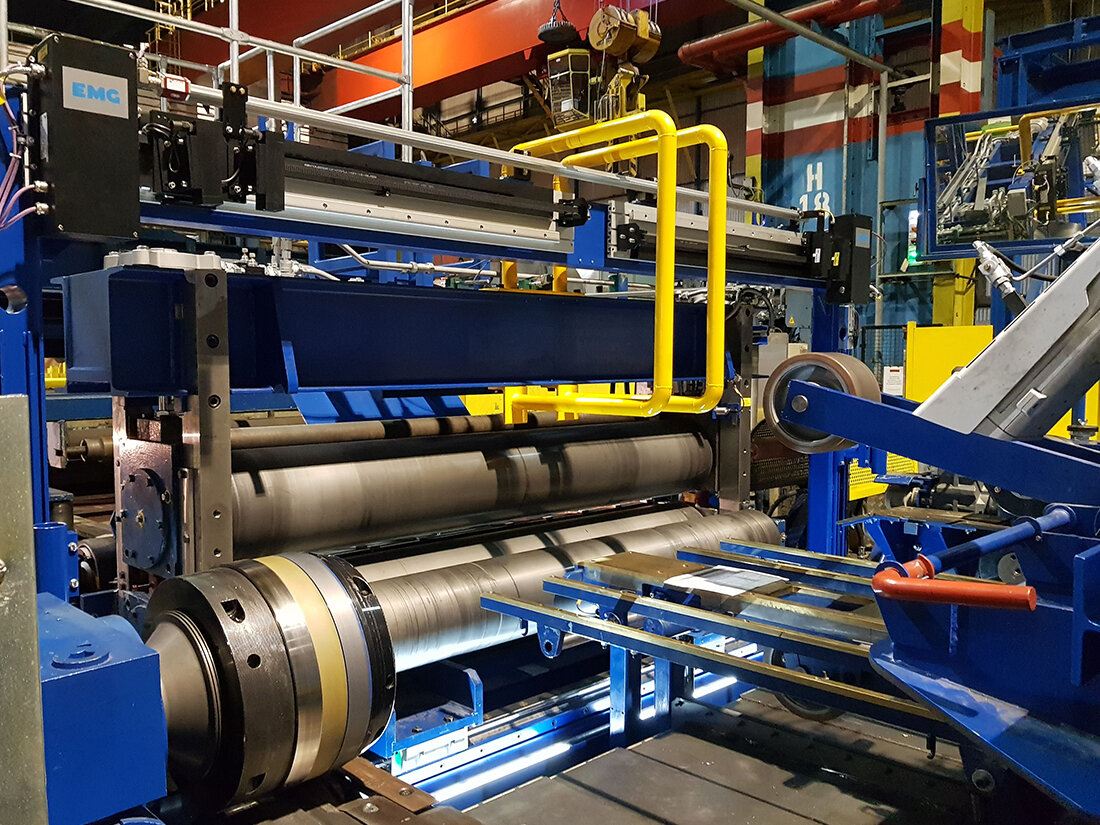

Ternium erweitert sein Pesquería Industrial Center in Mexiko mit DUMA-BANDZINK-Ausrüstung

Mönchengladbach, 15. Oktober 2022

Mönchengladbach, 15. Oktober 2022

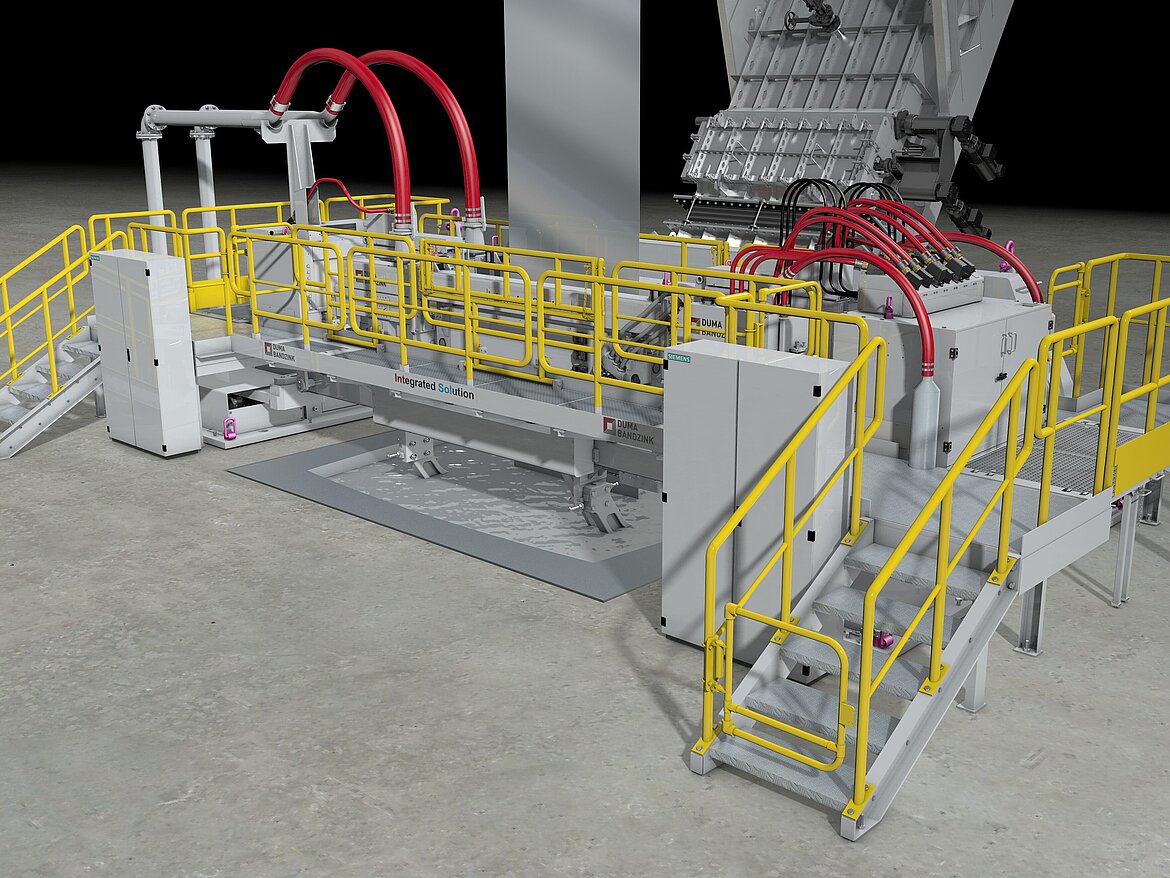

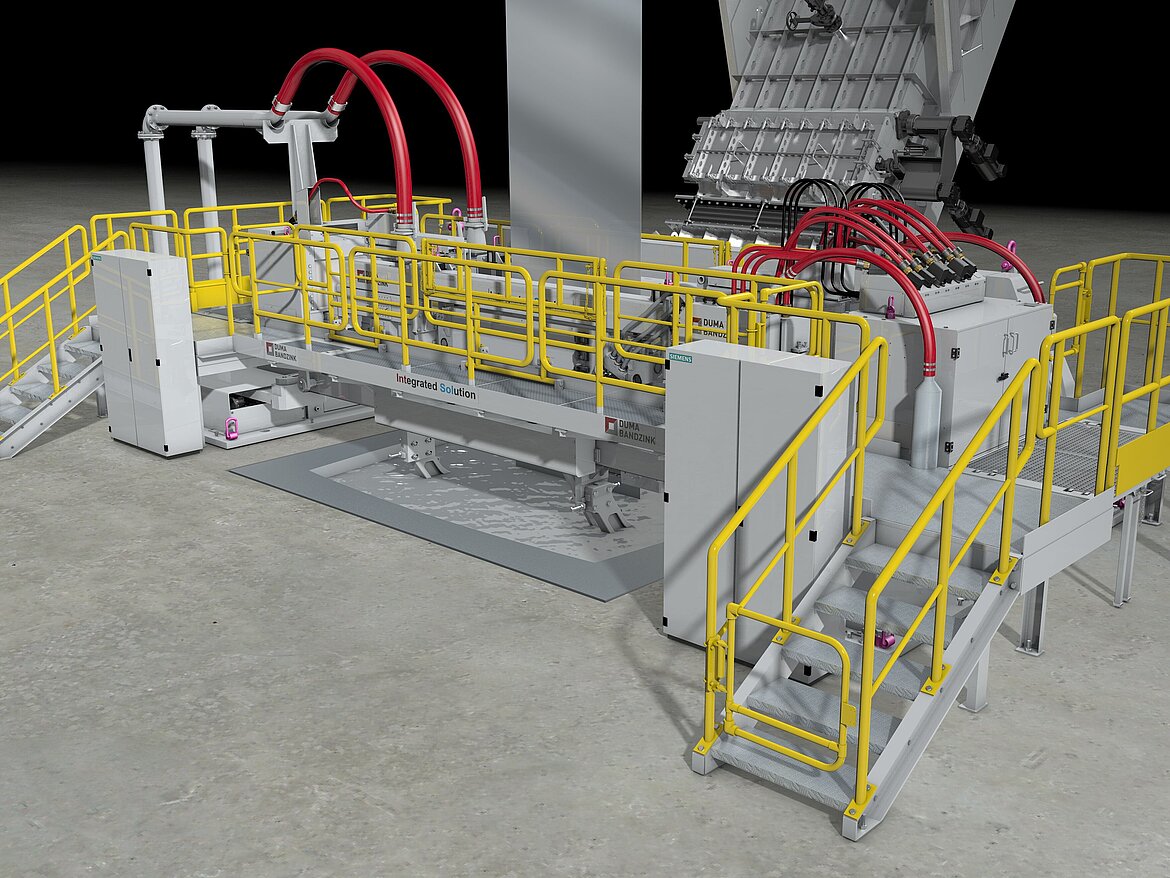

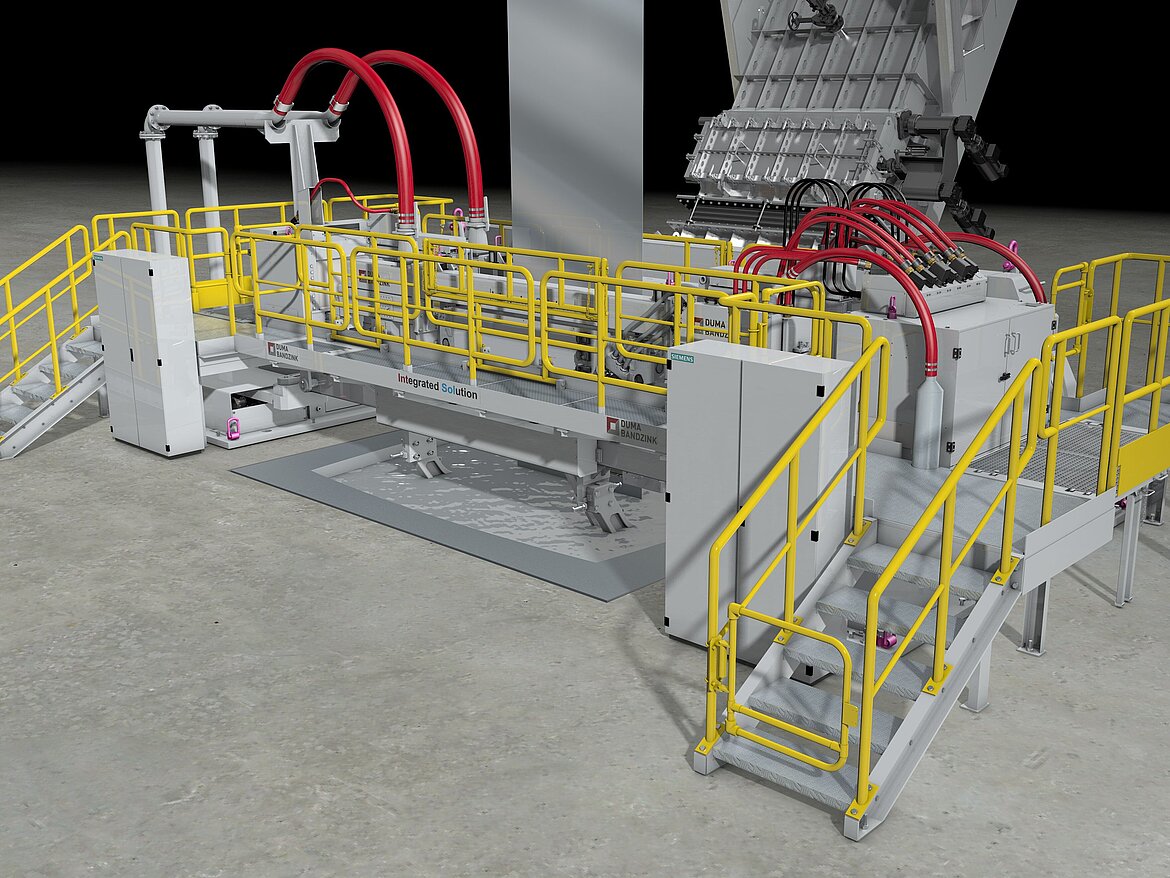

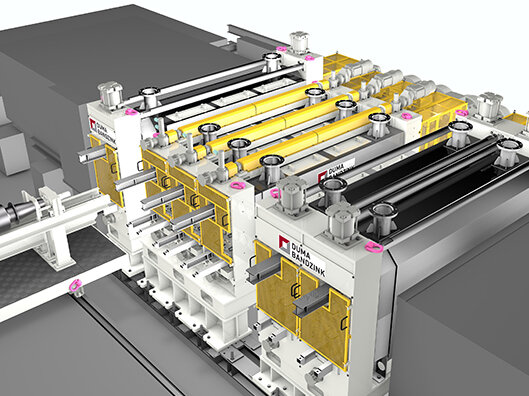

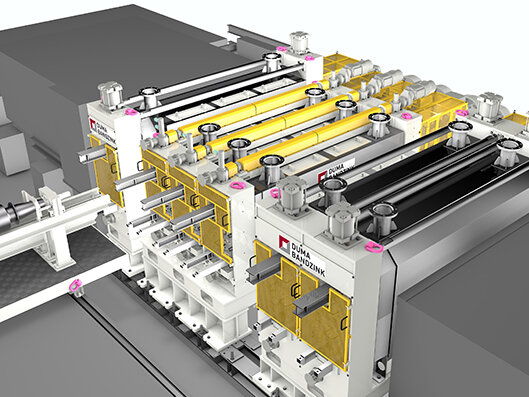

Neue Thyssenkrupp Feuerverzinkungslinie in Dortmund produziert mit Package Units

Mönchengladbach, 14. September 2022

Mönchengladbach, 14. September 2022

Neuer Reinigungsabschnitt für Cleveland Cliff Kote in New Carlisle, Indiana, USA

Mönchengladbach, 16. September 2019

Mönchengladbach, 16. September 2019

DUMA-BANDZINK liefert die Teilkomponente Abstreifdüse an Steel Dynamics Inc. für den Standort Sinton, Texas

Produkte

Karriere

Möchten Sie gerne Teil unseres Teams werden? Über unsere Stellensuche finden Sie unsere aktuellen Stellenangebote. Wir freuen uns auf Ihre Bewerbung.

→ Stellenanzeigen

Zufriedene und engagierte Mitarbeiter sind das wichtigste Kapital unseres Unternehmens. Daher ist es uns besonders wichtig, für unsere Mitarbeiter ein angenehmes und motivierendes Arbeitsumfeld zu schaffen, um eine langfristige Mitarbeiterbindung sicherzustellen.

→ Erfahren Sie mehr über unsere Vorteile

Kontakt

Haben Sie Fragen oder Anliegen? Jetzt Kontakt aufnehmen!

Social media

Kennen Sie schon unsere Linkedin-Seiten?