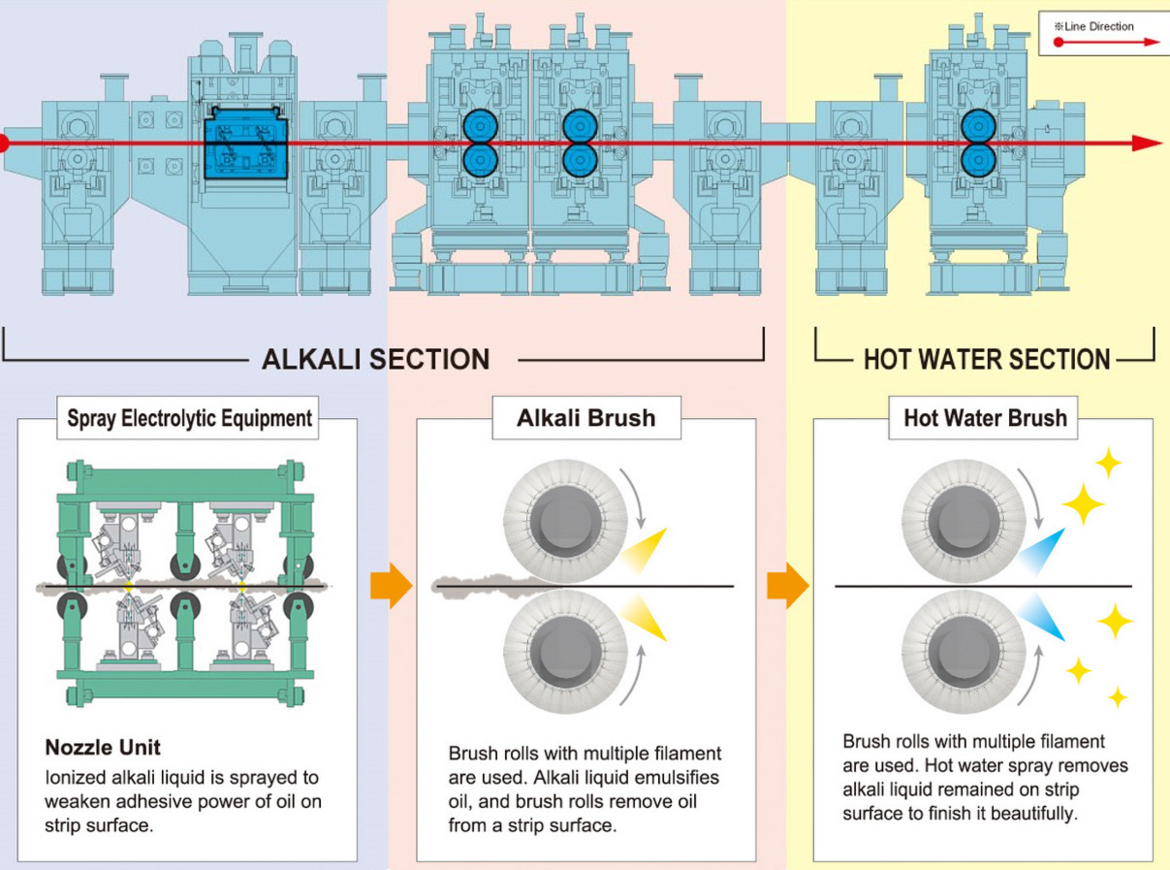

The quality demand from customers in the Cleaning Section of Continuous Processing Lines is highly increasing. Our system is one of the solutions to achieve this increased demand. It focuses on removing oil and irons in the alkali section and taking residuals away in the hot water section of the line to achieve the final cleaning result.

We are cooperating with the Japanese cleaning section expert Hotani, to provide established premium technology to our clients.

Spray Electrolytic Equipment

The unique spray electrolytic system is used in the entry of the alkali section. It specializes in weakening the adhesive power of residual oil stuck on the strip by spraying ionized alkali solution onto the surface. In combination with the following brushing equipment, it maximizes the cleaning efficiency.

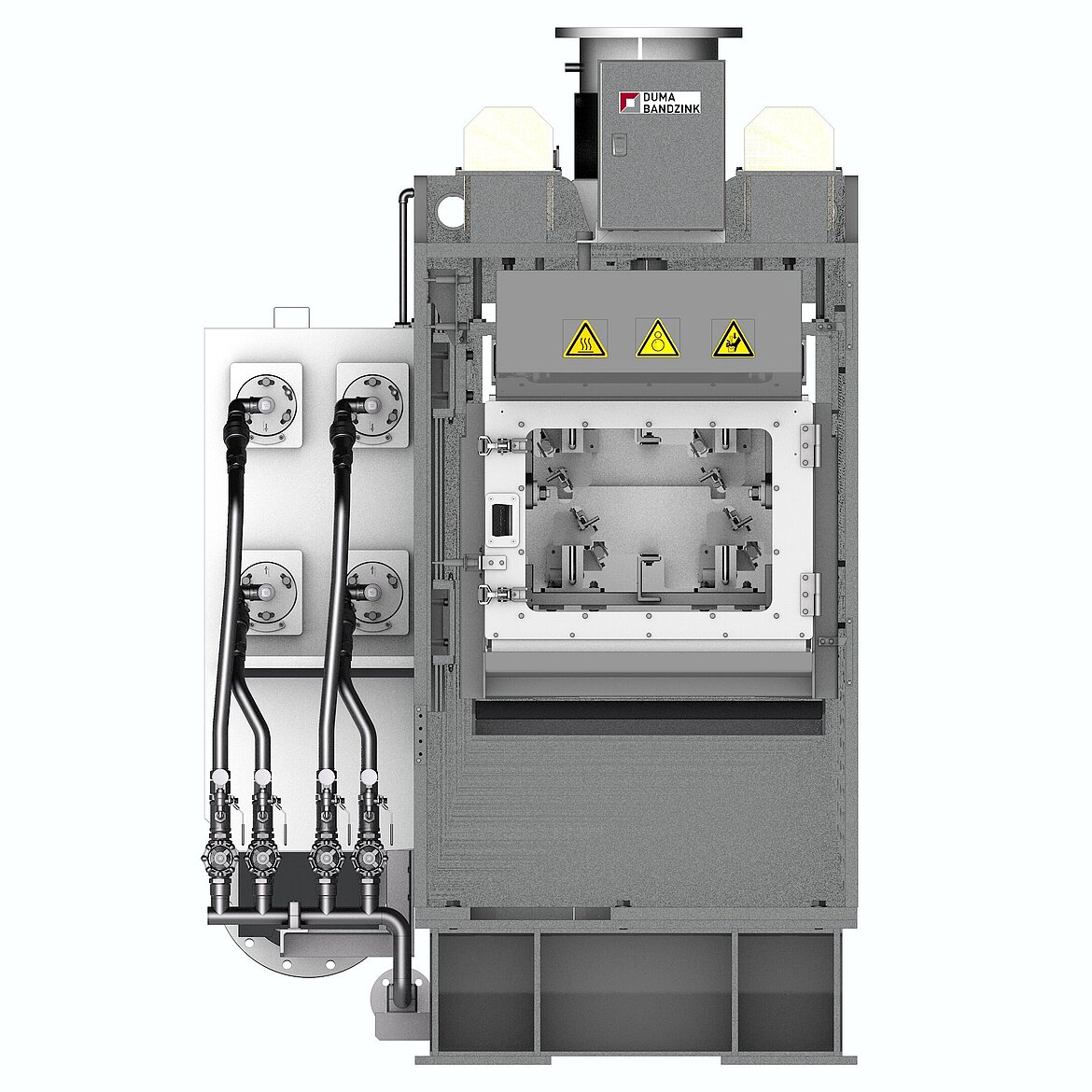

Brushing Equipment

The brushing equipment and brush types - ranging from mild cleaning to highly abrasive brushes – are individually selected for the customers cleaning requirements. The brushing equipment includes a variety of features to increase cleaning performance and lifetime of brushes. This includes automatic brush control, brush oscillation and automatic spray angle adjustment with flow monitoring.